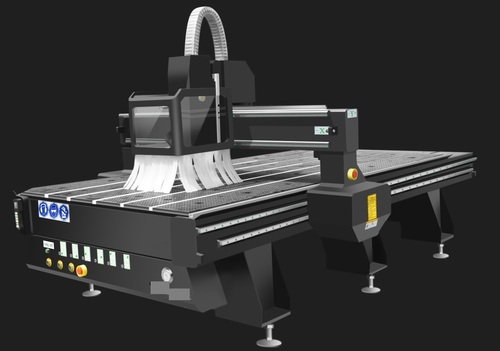

Automatic Edge band machine compact series

Price 934000 INR/ Unit

Automatic Edge band machine compact series Specification

- Product Type

- Woodworking Machine

- Machine Type

- Other

- Machine Style

- Horizontal

- Capacity

- 100 Pcs/min

- Voltage

- 415 Volt (v)

- Power

- Electric

- Automation

- Automatic

- Motor

- 8.5

- Speed

- 14-20-23 m/m

- Dimension (L*W*H)

- 3000X685X1250 Millimeter (mm)

- Weight

- 890 Kilograms (kg)

- Color

- gray

- Warranty

- 1

Automatic Edge band machine compact series Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Ex. Work Gujarat chennai

- Payment Terms

- Cash in Advance (CID), Cheque, Telegraphic Transfer (T/T)

- Supply Ability

- 100 Units Per Year

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Within a certain price range free samples are available

- Packaging Details

- international standard packing

- Main Export Market(s)

- Asia, North America, Middle East, Africa

- Main Domestic Market

- All India

- Certifications

- MSME

About Automatic Edge band machine compact series

Total Power : 8.49 Kw

Overall dimensions : 2975(L) x685(w) x1245(H) mm

Feed Speed :14-20-23 m / min

The thickness of the sheet metal :10-60mm

Sheet metal width : > 60mm

Length of panel : > 120mm

Sealing tape thickness : 0.42mm

Working Pressure :0.7 Mpa

Weight : 890 kg

Advanced Automation for Seamless Workflow

This compact series edge banding machine revolutionizes furniture manufacturing through full automation, ensuring minimal manual intervention and optimum productivity. Operators benefit from streamlined processes, consistent results, and decreased downtime, thanks to its high-speed and robust design. The horizontal configuration suits a wide range of workshop layouts, saving valuable floor space and simplifying operator access.

Built for Durability and High Output

Constructed with industrial-grade materials and a powerful 8.5 motor, this edge band machine supports intense workloads and continuous operation. Capable of processing up to 100 pieces per minute at varying speeds, it is engineered for demanding export and wholesale environments. Its sturdy build and considerable weight of 890 kg contribute to vibration-free, precise edge banding every cycle.

FAQs of Automatic Edge band machine compact series:

Q: How does the automation in this edge banding machine benefit production efficiency?

A: The automation of the Compact Series edge banding machine minimizes manual tasks, leading to faster processing times and consistent quality. This allows operators to achieve greater throughput and reduces the chance of human error, directly boosting production efficiency.Q: What types of edges and materials can this machine handle?

A: Designed for versatility, the machine efficiently applies edge bands to various panel materials commonly used in furniture manufacturing, such as MDF, plywood, and particle board, ensuring a precise and durable finish every time.Q: When is scheduled maintenance recommended for this edge banding machine?

A: Regular maintenance should be performed in accordance with the manufacturers recommendationstypically after a certain number of operating hours or monthly checksto keep the machine running smoothly and within the scope of the 1-year warranty.Q: Where is this machine manufactured and exported from?

A: This edge banding machine is produced and exported from China, serving global markets through a network of suppliers, service providers, and wholesalers.Q: What is the process for operating the machine safely?

A: To operate the machine safely, users should familiarize themselves with the instruction manual, ensure proper electrical connections (415 V), and follow lockout/tagout procedures during maintenance. The horizontal layout allows for safe loading and unloading of panels.Q: How can businesses integrate this machine into existing production lines?

A: Thanks to its compact dimensions and straightforward electric power requirement, the machine can be easily incorporated into most production lines, requiring minimal workspace adjustments and enabling seamless workflow integration.Q: What are the key benefits of using the Compact Series automatic edge band machine?

A: Key benefits include high-speed edge banding (up to 100 pieces per minute), automation that reduces labor costs, a sturdy gray finish for industrial longevity, reliable service with a 1-year warranty, and consistent, professional results on every panel.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Panel Line machineries Category

COLD PRESS MACHINE

Price 1 INR / Unit

Minimum Order Quantity : 1 Unit

Power : Electric

Weight : 2000 Kilograms (kg)

Machine Style : Vertical

Warranty : 1

CNC Router Machine with brand

Price 1.00 INR / Set

Minimum Order Quantity : 1 Unit

Power : Electric

Weight : 1300 Kilograms (kg)

Machine Style : Vertical

Warranty : 1 year

Cold Press Machine

Price 1 INR / Set

Minimum Order Quantity : 1 Piece

Power : Electric

Weight : 2000 Kilograms (kg)

Machine Style : Horizontal

Warranty : 1 year

Hot Press Machine

Price 1.0 INR / Piece

Minimum Order Quantity : 1 Piece

Power : Electric

Weight : 5500 Kilograms (kg)

Machine Style : Horizontal

Warranty : 1 year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS