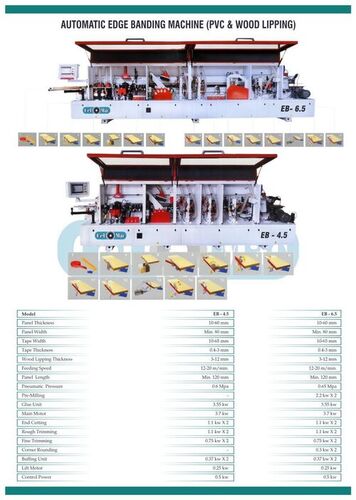

Edge band machine for PVC and Wood lipping

Price 1.0 INR/ Nos

Edge band machine for PVC and Wood lipping Specification

- Machine Type

- Automatic Edge Banding

- Color

- White & Blue

- Output

- Smooth and Sealed Panel Edges

- Weight

- 650 kg

- Automation

- Fully Automatic

- Production Capacity

- 200-300 pieces/hour

- Bending Angle

- 90 maximum

- Raw Material

- PVC, Wood Lipping

- Bending Strength

- High Precision Bending for Board Edges

- Power

- 3.5 kW

- Motor Speed

- 2850 RPM

- Condition

- NEW

- Dimension (L*W*H)

- 3900 mm x 900 mm x 1600 mm

- Phase

- Three Phase

- Bending Speed

- 12-18 m/min

- Capacity

- Continuous Operation

- Bend Radius

- Minimum 20 mm

- Voltage

- 380 V

- Usage

- Industrial Furniture Making, Panel Processing

- Product Type

- Edge Banding Machine

- Dust Extraction Port Diameter

- 100 mm

- Control System

- Digital PLC Control Panel

- Heating Power

- 1.2 kW

- Panel Thickness Range

- 10-60 mm

- Edge Band Thickness Range

- 0.4-3 mm

- Feed Speed

- Adjustable, up to 18 m/min

- Worktable Height

- 850 mm

- Noise Level

- < 78 dB

- Glue Pot Capacity

- 1.5 kg

- Air Pressure Required

- 0.6 MPa

- Service Support

- Onsite Installation & Training

Edge band machine for PVC and Wood lipping Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 10 Pieces Per Month

- Delivery Time

- 30 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Packaging Details

- International Standard Packing

- Main Export Market(s)

- Middle East, Asia, Africa

- Main Domestic Market

- All India

About Edge band machine for PVC and Wood lipping

Key Features & Industrial Applications

The Edge band machine excels in both PVC and wood lipping, making it ideal for industrial furniture manufacturing and panel processing. With fully automatic operation, adjustable feed speed, and a supreme digital PLC control system, productivity rates soar between 200-300 pieces per hour. Designed for continuous use, its classic construction favors heavy-duty tasks, providing high precision, smooth finishes, and versatile panel thickness options for quality results.

Export, Certification & Secure Shipping

Our Edge band machine ensures secure shipping from major FOB ports in China, complete with lofty certification standards that assure premium quality. Packaging details are meticulously designed for classic protection to support both supply and long-distance transport. The asking price and terms are flexible for exporters, service providers, suppliers, traders, and wholesalers. Ready stock and strong supply chains guarantee fast fulfillment and reliable delivery worldwide.

FAQ's of Edge band machine for PVC and Wood lipping:

Q: How does the Edge band machine improve panel edge finishing?

A: The machine uses high precision bending and adjustable feed speed to provide smooth, sealed edges on panels, enhancing both appearance and durability.Q: What is the process for onsite installation and training?

A: Expert technicians will install the machine at your site and provide comprehensive training for operators to ensure optimal usage and maintenance.Q: When is the best time to use this machine in furniture making?

A: The machine is ideal for finishing work during panel processing and assembly, ensuring a professional look and supreme bonding strength before final delivery.Q: Where is the Edge band machine supplied from?

A: It is securely shipped from leading FOB ports in China and supplied to clients globally, backed by efficient logistics and classic packaging standards.Q: What are the benefits of the machine's fully automatic operation?

A: Fully automatic operation streamlines production, reduces manual errors, and boosts output, making it highly efficient for industrial-scale manufacturing.Q: How is packaging managed for export orders?

A: Packaging is designed to secure the machine during transit, protecting against damage with robust, classic materials that meet certification requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Edge Banding Machine Category

Manual Edge Band Machine

Minimum Order Quantity : 1 Unit

Product Type : Manual Edge Band Machine

Place of Origin : India

Usage : Industrial

Condition : 1

Voltage : 415 Volt (v)

Manual Wood Edge Banding Machine

Minimum Order Quantity : 1 Unit

Product Type : Manual Wood Edge Banding Machine

Place of Origin : India

Usage : Industrial

Condition : 1

Voltage : 420 Volt (v)

Automatic Wood Edge Bander Machine

Minimum Order Quantity : 1 Unit

Product Type : Automatic Wood Edge Bander Machine

Place of Origin : India

Usage : Industrial

Condition : 1

Voltage : 420 Volt (v)

Automatic Edge Banding Machine For Acyrlic Edge Banding

Minimum Order Quantity : 1 Unit

Product Type : Automatic Edge Banding Machine For Acyrlic Edge Banding

Place of Origin : India

Usage : Industrial

Condition : 1

Voltage : 415 Volt (v)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS